LASER RESISTOR TRIMMING

Circuit and component, chip resistor and semiconductor wafer trimming.

During the final stages of component or circuit manufacture, resistor trimming employs a laser to ablate a small amount of resistor material, resulting in an increase in resistance through a reduction in the resistor’s effective cross section. Whether you are using thick or thin film on virtually any substrate, PPI Systems can design a RapiTrim laser resistor trimming system to match your application using flying probe, probe card or custom probing for active or passive trimming.

PPI Systems offers unique RapiTrim resistor trimming systems for each resistor trimming market. Every type of resistor trimmer is designed around unique laser, measurement and automation options. IR or Green laser, flying probe, probe card or custom measurement, manual or with automation – a solution is available for each application.

Thick and Thin Film

Thick and thin film resistors are manufactured as components or as part of circuits, usually on a ceramic or silicon base. Thin film resistors have a typical thickness of <1 µm, while thick films are usually 10-30 µm.

Thin film resistors can be trimmed to tighter tolerances and exhibit better stability and temperature coefficients. Thick film resistors are less expensive to manufacture and are used if moisture resistance is an issue or where higher specifications are not necessary.

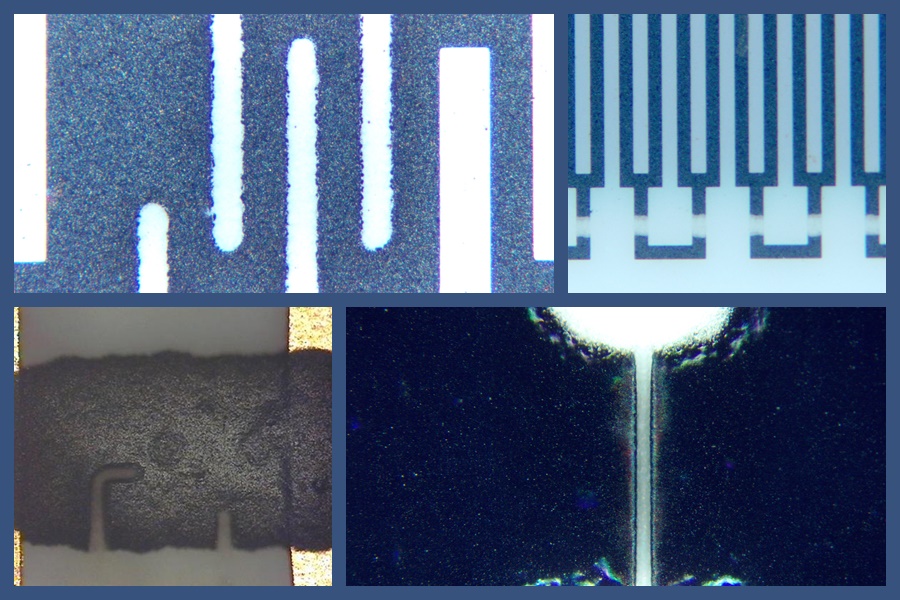

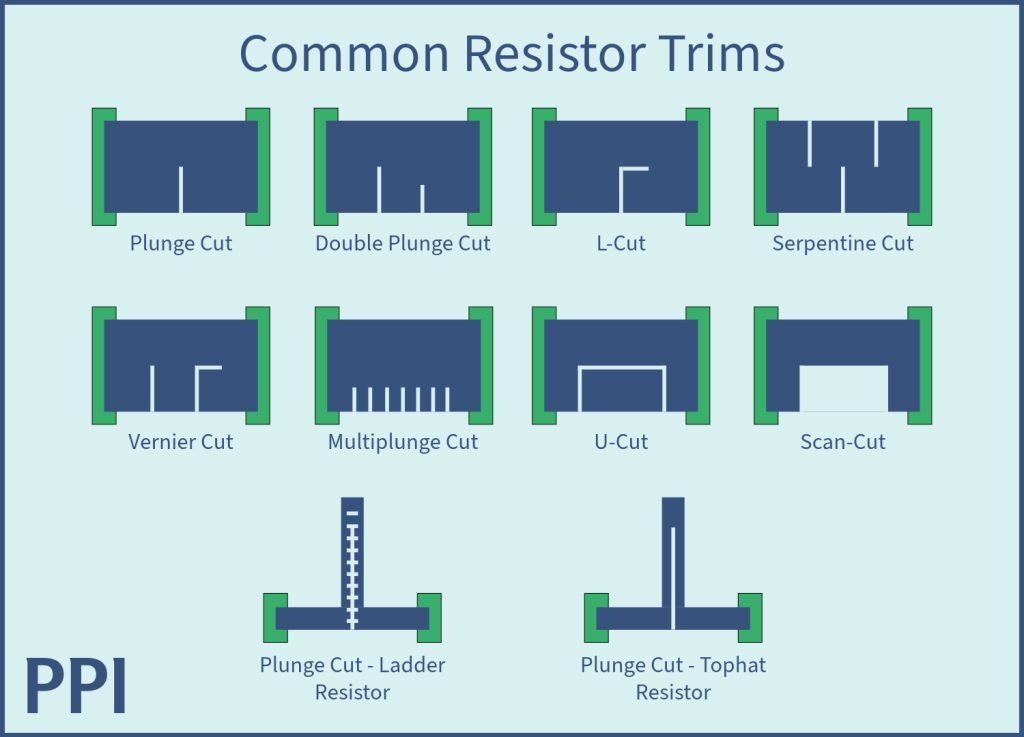

Resistor Trim Types

There are a variety of cut or trim types used to laser trim resistors. Each has benefits and limitations, and is chosen with the application requirement, production rate, cost and intended tolerance in mind. Combinations of these trim types are also employed. Manual and custom trims are available.

Measurement Types

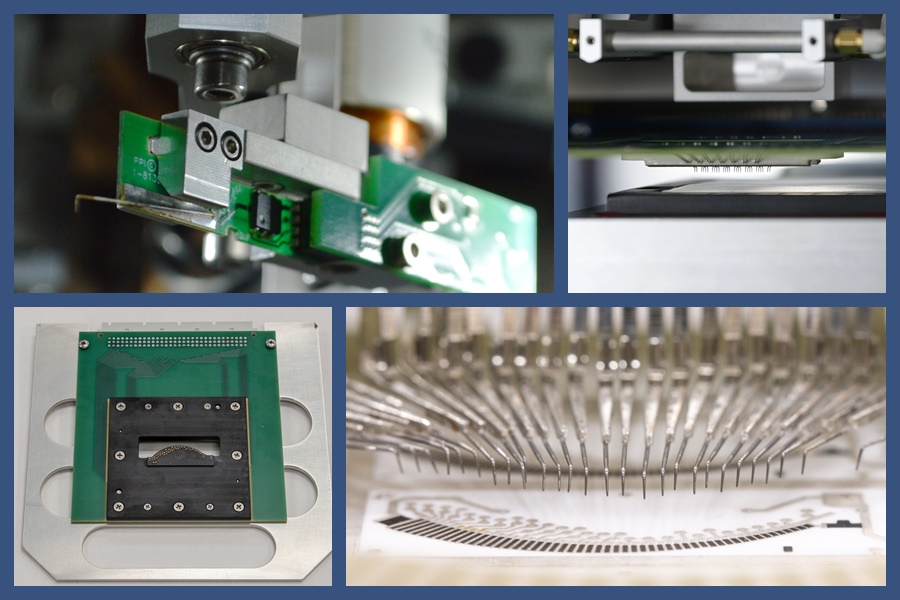

PPI Systems offers both flying probe and probe card measurement options along with custom probing solutions. Flying probe systems are a perfect fit for lower volume, high mix manufacturers that wish to avoid the restrictions imposed by probe cards and the high cost of making and maintaining a large number of probe cards.

For high volume, low mix customers, probe card systems provide the highest possible speeds. PPI can provide unbiased advice on which technique will benefit your application.

Active or Passive Trimming

Passive trimming involves the adjustment of a single resistor to a required value, while active trimming alters the entire circuit output, traditionally voltage, switching threshold or frequency. Both can be used with IR and Green lasers. Active trimmers allow test connections to be made through a combination of application-specific top-side probing, bottom-side probing, flying probes or custom fixtures.

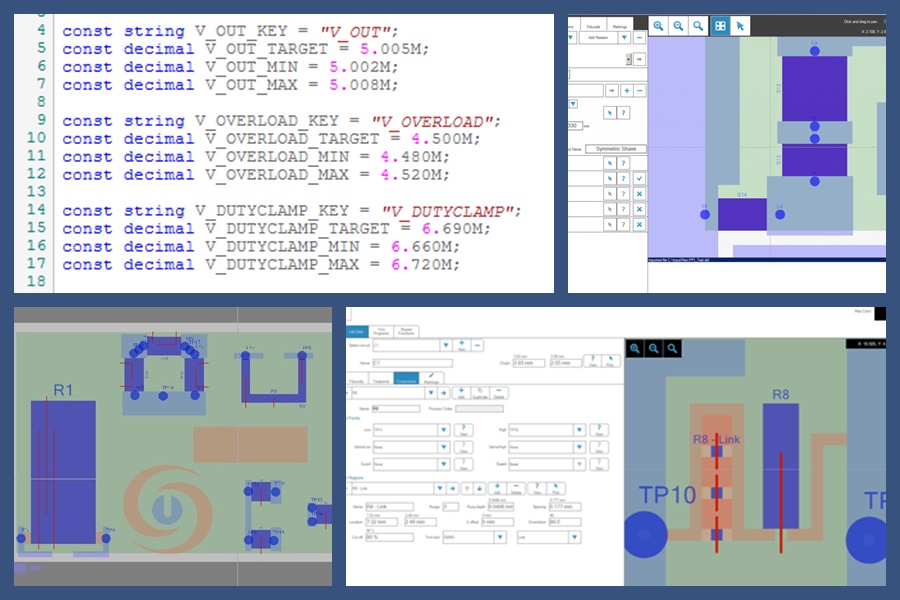

PPI provides full support for software control and connection of external instruments with integrated active trim sequence scripting.

Automated DXF Import and Process Sequence Customization

RapiTrim systems have an intuitive graphical user interface that offers unmatched ease of use for both operators and process engineers. All machine setup and calibration controls, job and process settings, vision and process map, status and diagnostic information are easily accessible. ProSys provides automated DXF import to streamline job creation and process sequence customization to create sequences of defined sub-tasks.