PPI Systems offers a wide variety of custom testing solutions which may incorporate a completely unique testing option or combinations of the previously noted testing types as specified by customer applications.

Blog

Brian Graydon | Apr 22 | 4 min read

Laser Resistor Trimming Test Options

Updated: Apr 23

Testing a printed circuit board, hybrid circuit or component can employ a variety of methods which include flying probes, probe cards, pogo pins or other custom testing options. Each type of testing accomplishes the same goal of contacting the device under test (DUT), but they do it in different ways which are application specific. The question is, where should each be used?

High-Mix, Low Volume Applications

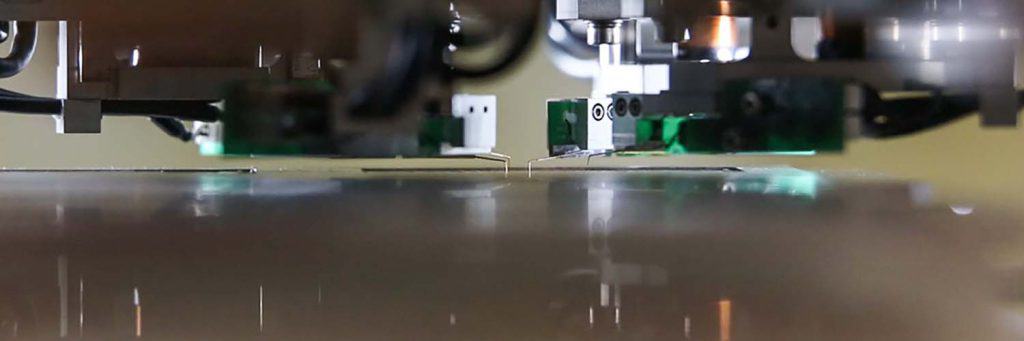

Flying-probe testing systems employ precision electro-mechanical motion to access various components on printed circuit assemblies. RapiTrim systems have four flying probes with a range of tip sizes and materials for single or full Kelvin (double tip) probes.

Flying probe systems have significant advantages over probe-card systems in high-mix, low volume applications:

No custom fixture required: The probes move by software control to make contact with test points and thus the probe card fixture is not required.

Changes to the job are made easily: Any changes that are needed for different pad positions or new components are made completely in the software. No changes to hardware are needed, greatly reducing set-up times.

Reduction in test development time: Creation of the testing protocol can be developed relatively quickly from PCB design files. Thus, there is no design or manufacturing time needed for a new mechanical fixture. Development of a test program for a flying probe system only requires the PCB files.

Cost: There is a high cost associated with designing, manufacturing, storing and changing probe cards, while a flying probe system only have the cost of replacement tips during system operation, which is a fraction of the cost of a single probe card.

Low Mix, High Volume Applications

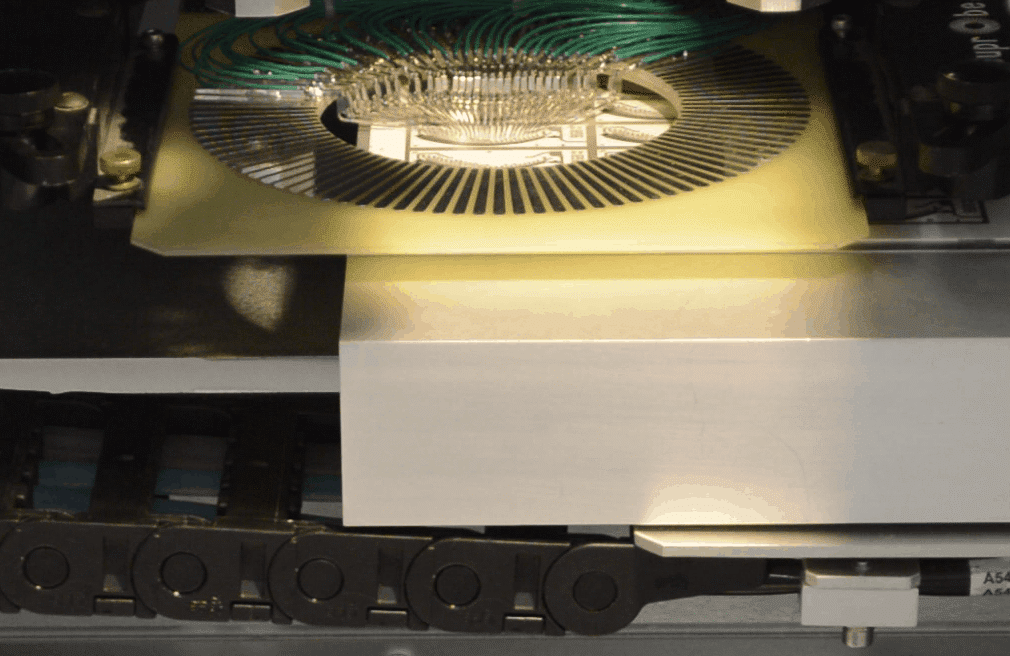

Probe card systems were first introduced in the 1970’s and have evolved to provide fast test throughput for high volume of simple circuit or component layouts. This would apply to layouts that can be accommodated with a single probe card.

Advantages include:

Fastest possible cycle time: Since probe cards typically access multiple circuits or components at a time, the overhead time moving a new area of the substrate under the probe card is shared, improving throughput.

Easy program generation: RapiTrim customers still benefit from PPI’s auto-import function, quickly moving from a DXF to a ready-to-run job.

Specialized Testing Options

Pogo Pins

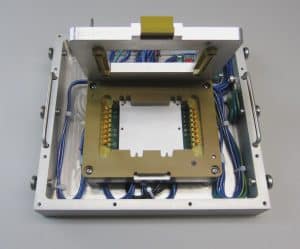

Pogo pins are spring-loaded connectors that have improved durability when compared to other type of electrical contacts. They are better able to manage mechanical shock and vibration. Each connector has an integrated spring which ensures the needed force with the contact plate. These pins have a low cost, are easy to source and form a strong, reliable connection.

A typical pogo fixture is designed for backside contact, allowing full access for the laser from the top. Overhead time for flying probe motion or probe card step-and-repeat motion is eliminated. This arrangement often provides the highest throughput solution for those high volume jobs. The fixtures can be easily exchanged for different part designs.

Active Trimming Fixtures

Specialized fixturing is created for active trimming systems which allow the circuit to be placed in its own holder which can then be added to the trimming system connecting to a custom made receptacle. The system then measures some aspect of functional circuit performance which feeds back to the control of the laser during trimming. All activity is integrated through the PPI interface.

These fixtures are designed at PPI Systems and are simple to install and remove, ensuring the fastest possible active trim cycle time.