VIDEOS

Visit our YouTube page for informative videos on laser resistor trimming and microvia drilling. For additional resources please contact PPI systems at info@ppisystems.com.

PPI Systems Laser Drilling and Resistor Trimming Systems

PPI Systems Profile

Based in Ottawa, Ontario, Canada, PPI designs and manufacturers turn-key laser drilling and resistor trimming systems for the electronic interconnect and component markets from it's 23,000 square foot production facility.

RapiTrim Laser Resistor Trimming Systems

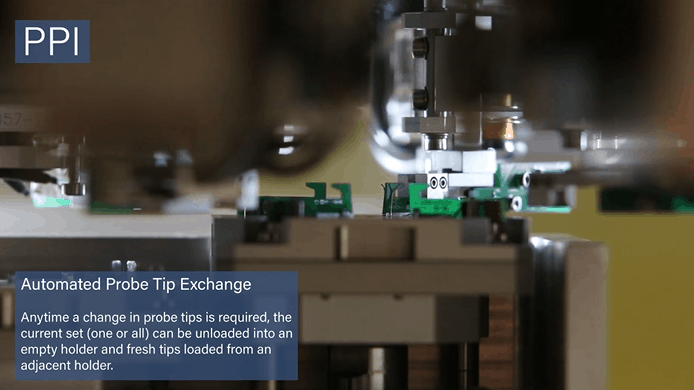

RapiTrim-C Automatic Probe Tip Exchange

Anytime a change in probe tips is required, the current set (one or all) can be unloaded into an empty holder and fresh tips loaded from an adjacent holder.

RapiTrim-C Flying Probe Demonstration

Ideally suited to high mix situations (frequent product changes), lots of new designs, smaller job lots, complex circuit layouts with high resistor counts.

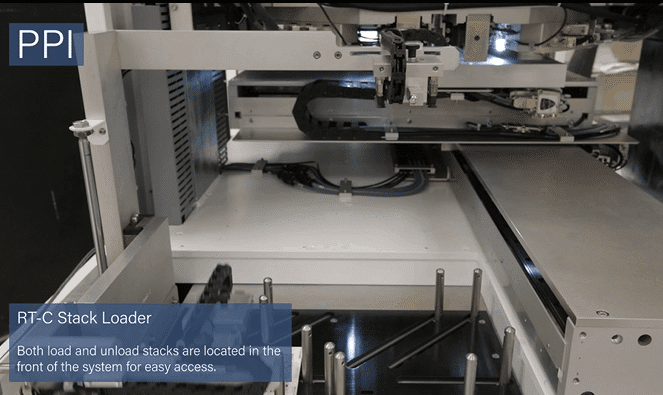

Stack Loader

Both load and unload stacks are located in the front of the system for easy access. Substrates up to 200 x 200 mm are loaded by vacuum pickup.

ProVia Laser Via Drilling Systems

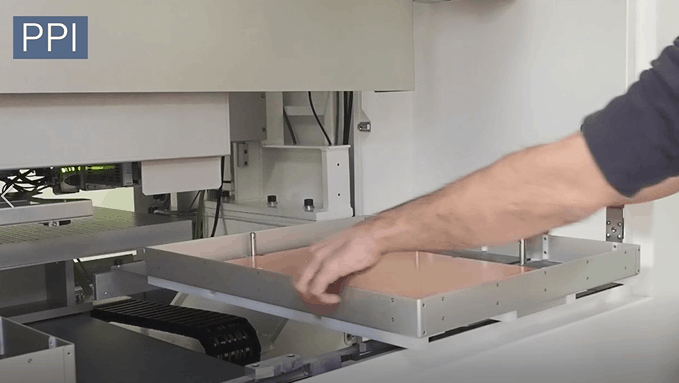

FP-UC Loader - Tray Removal

Demonstration of a tray removal and reload in a ProVia FP-UC dual CO2 and UV laser drilling system.

ProVia Laser Processing

Operation of a ProVia laser UV and CO2 via drilling system in the PPI main application laboratory.

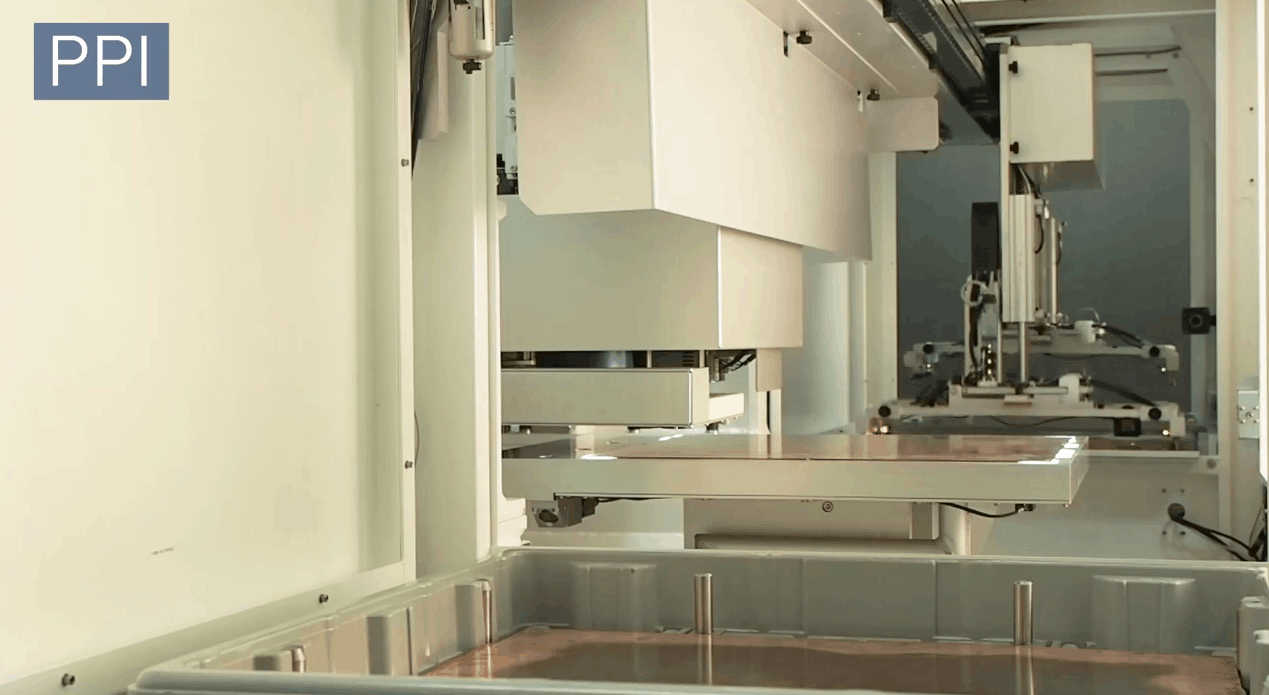

ProVia and RapiTrim Automation

This automation scheme applies to both the ProVia laser drillers / cutters and the RapiTrim fixtureless trim and test systems.

ProVia Compact Loader Operation

Short video demonstration of the compact loader operation on a ProVia FP-UC Laser Via Drilling System.