PROVIA LASER DRILLING

Dual Laser (UV + CO2)

Single Laser (CO2)

Single Laser (UV)

Optional Features

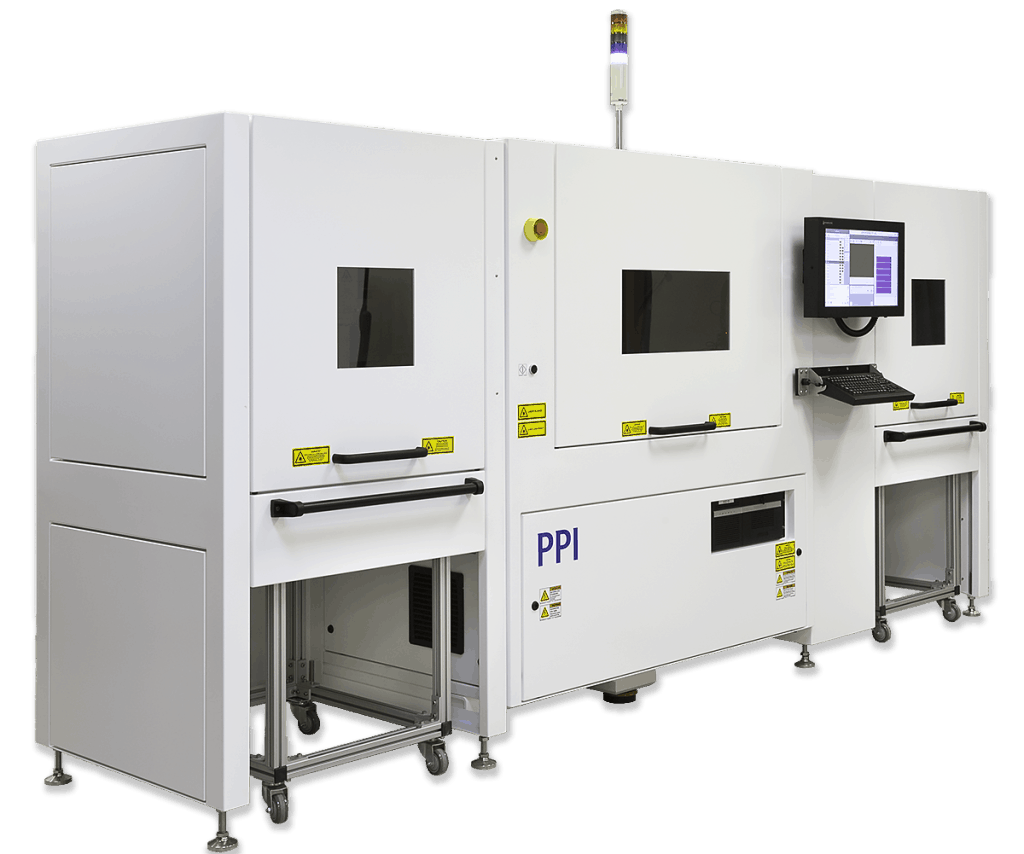

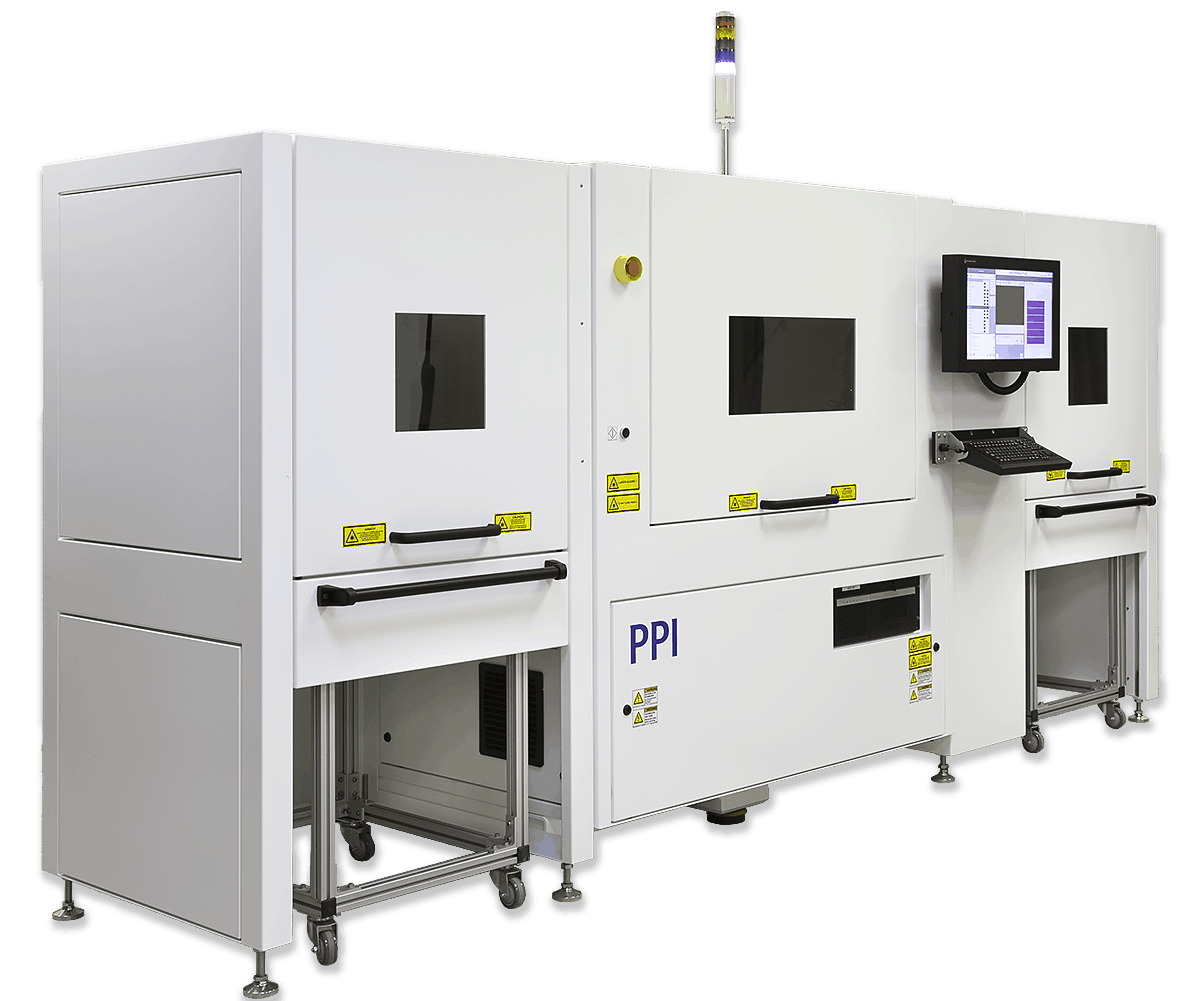

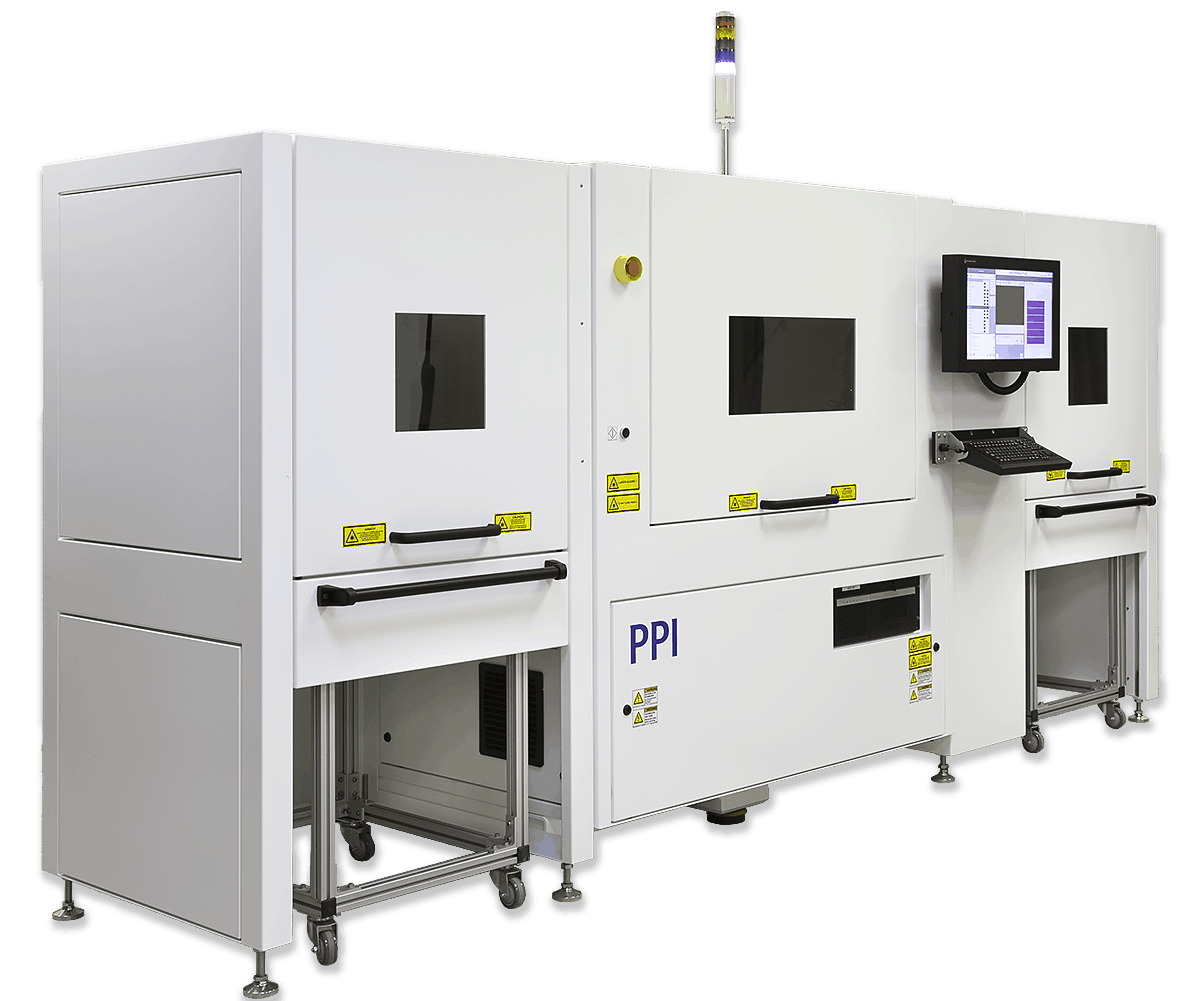

ProVia Drilling and Cutting Systems

ProVia systems are advanced volume production workstations for rigid, rigid-flex or flex panels, incorporating high performance beam positioning and laser control for high throughput drilling and routing of complex features.

Choose from Dual-laser (UV + CO2), UV, and CO2 lasers models:

- Dual or single laser systems

Single-laser systems available in dual-head, dual-panel processing configurations

All systems are roll-to-roll compatible

Standard or compact automation available

CO2 laser systems are appropriate for high speed drilling, cutting and skiving of dielectrics, while UV laser systems are able to drill and pattern copper and can provide higher process quality in many dielectrics. Whether your application is with glass or organic reinforced epoxies or non-reinforced materials (resin-coated foil or polyimide), there is a ProVia model to meet your requirements.

ProVia FP-UC Dual Laser Drilling System

ProVia FP-UC laser drilling and cutting systems incorporate both UV and CO2 lasers and scan heads. The CO2 laser is appropriate for high speed drilling, cutting and skiving of dielectrics, while the UV laser is able to machine copper and provide higher process quality in many dielectrics.

- Combining both laser sources (UV + CO2) into one system allows a simple, reliable process with a large process window

- Openings in the top copper with high accuracy using the UV laser

- CO2 lasers remove the dielelectric without damage to the top or bottom copper surfaces

- Each process step may be optimized independently

- Multistep processing allows automatic drilling of two-layer vias

ProVia FP-UC Dual Laser System

UV + CO2 Laser system, providing the broadest capability with optimum speed.

Article: The Benefits of Dual Laser Microvia Drilling

An article outlining hybrid laser (UV + CO2) microvia drilling

ProVia FP-UC Datasheet

ProVia FP-UC laser microvia drilling system datasheet

ProVia FP-C CO2 Laser Drilling System

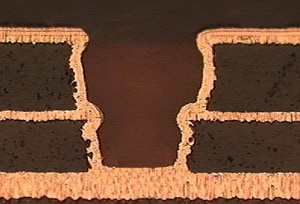

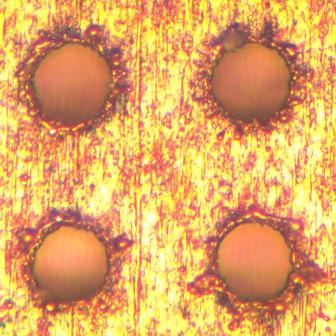

The mid-infrared wavelength of the CO2 laser is strongly absorbed by common dielectric materials and strongly reflected by copper. As a result a large CO2 spot can over-fill an opening in the copper (created by a UV laser or chemically etched) without risk of damage to the top layer of copper surrounding the hole (the capture pad).

- Repeated pulses will ablate the dielectric (including woven glass reinforcement)

- The process self-terminates on the stop layer as the beam is reflected by the copper

ProVia FP-C CO2 Laser Drilling System

CO2 via drilling system for cost effective HDI Via drilling

ProVia FP-C Datasheet

ProVia FP-C laser microvia drilling system datasheet

ProVia FP-U UV Laser Drilling System

The UV laser is absorbed by both copper and dielectric materials. A high intensity spot is needed to drill through copper while lower intensity is adequate for some dielectrics, notably polyimide and acrylic adhesives used in flexible printed circuits. The high intensity spot can be used to drill through-holes in flex material, while a multi-step process with both high intensity and low intensity process steps can be used to drill blind holes.

- Superior drilling and cutting quality in copper and many dielectrics

- High performance beam positioning for rapid, accurate panel processing.

- Excellent offering for high-mix, flexible manufacturing environments

ProVia FP-U UV Laser Drilling System

UV system, providing high speed processing of copper, and high quality drilling and cutting of dielectric material

ProVia FP-U Datasheet

ProVia FP-U laser microvia drilling system datasheet

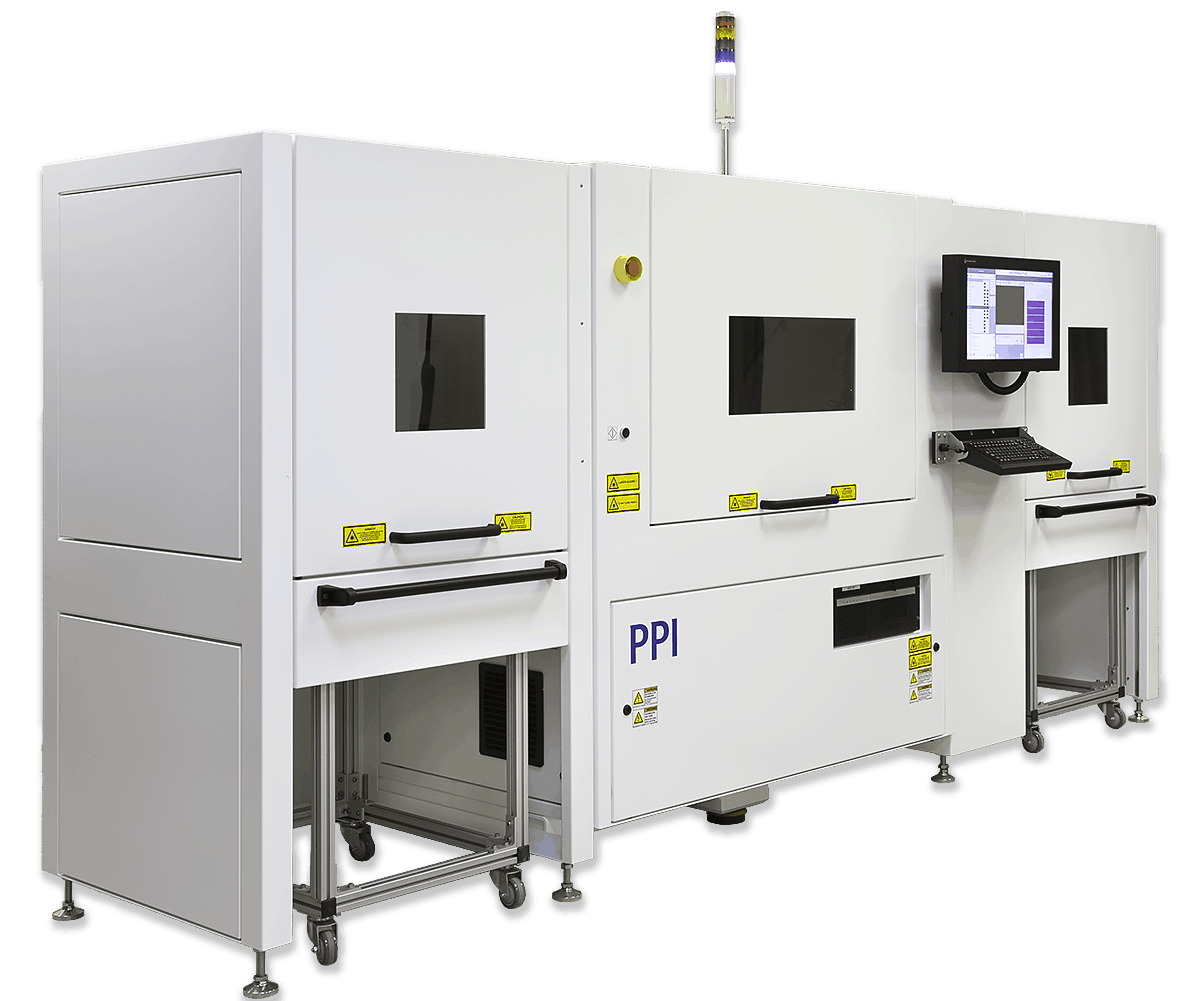

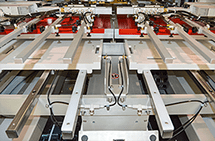

ProVia Laser Drilling System Optional Features

ProVia laser via drilling and cutting systems provide a full set of options including: autoloaders, inspection microscopes, dual-head, dual panel drilling and more.

ProVia Optional Features

ProVia systems feature many loading and fixturing options

Drilling Videos

Videos include automation, tray loading, compact loader operation and more.

Laser Drilling and Cutting FAQ

Common questions asked by our microvia drilling customers.